Join community map

The M45 server has kindly agreed to host a Bitumen community map that you can join.

Find the info at: The M45 discord server

Big production update

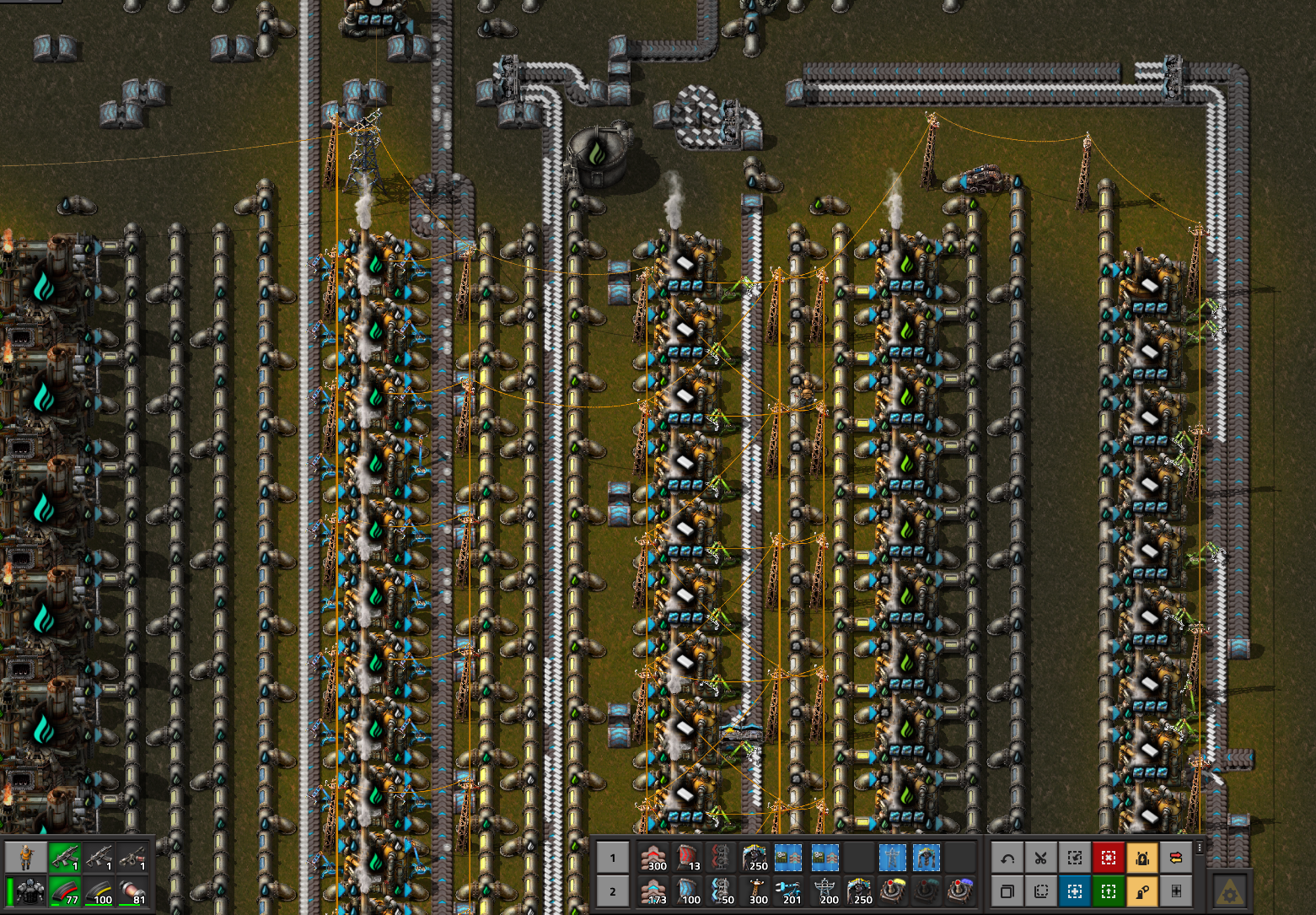

As research is ticking in, new technologies keeps getting ready for your production lines. Next update will see a lot of new high end production equipment being available: Advanced precision metal cutting and grinding processes, that makes for higher performance. This also opens up the possibility for more specialized production lines, where the assemblers are custom fitted for your exact production needs. Again this is done to serve the need for higher performance in your production lines.

These are a few of the items that will be available:

A primitive start

Using iron-based baceria as a source of iron is perhaps a bit primitive. On the other hand, is has very few technological requirements and will get you started - with a bit of work. From this you can transit into basegame techonologies.

Injection molds

At the advanced end a lot of new technologies are available. The ability to form plastic with high accuracy and in complex shapes in just one operation is key to efficient high volume production of all sorts of products. The making of each specialized injection mold is demanding in terms of accuracy and finish, but pays off by providing a fast and reliable production tool.

Grinding tools

Lapping with abrasive diamond pastes can yield high quality production tools that conforms to very strict tolerances and ensures both speed and longevity of production equipment.

Progressive stamping dies

Stamped metal has huge advantages over cast or machined parts: By forging along the metals own structural lines strength and endurance is enhanced. The progressive stamping die gives modern production items the benefits that otherwise would require handcrafting by a blacksmith.

The Challenge

Factorio Bitumen is meant to be a challenge and interesting to experienced factorio engineers. Not by having many tedious chokepoints, but rather by being a genuine complex affair, where your resources will be at times streched thin on the ground.

At the same time realism is a priority, in the sense that a fairly good representation of a variety of techonologies is implemented. We are aiming for a good balance between a fun experience and a fairly interesting journey. There is not always a big difference between playing and learning. And if they blend together at times, that is a very good thing.

These are some of the present technologies:

Peat and Tar production

"Peat is harvested as a source of fuel in certain parts of the offworld colonies. In class-d worlds there are on average about 4 trillion cubic metres (5.2 trillion cubic yards) of peat , covering a total of around 2% of the global land area. Over time, the formation of peat is often the first step in the geological formation of fossil fuels such as coal, particularly low-grade coal such as lignite" (HGG, 2234).

Peat is readily turned into tar by anoxic heating, which makes for a more convenient production fuel.

Peat is harvested by simply shoveling it out of the ground.

Ash production

To the casual observer ash is just a waste product. But in reality ash is a valuable chemical product as it can be processed into potassium. Potassium is our main base or akaline in both potassium-hydroxide and potassium-nitrate. At a more advanced stage this leads to production of the powerful oxidizer potassium permanganate (when combined with manganese products) using the more advanced technologies.

Drug furnace

The drug furnace is a specialized tool for burning different kinds of wood, charcoal and ashes. The use of a specialized drug furnace makes the basis for akaline chemistry as it provides ash from burned wood. The use of a specialized drug furnace makes the basis for akaline chemistry as it provides ash from burned wood. The process also yields charcoal which is used as an agent for water purification. The drug furnace also has functionality that lets your strip copper wire from wooden poles before burning them, making the process more friendly for the environment and more economic in terms of resources.

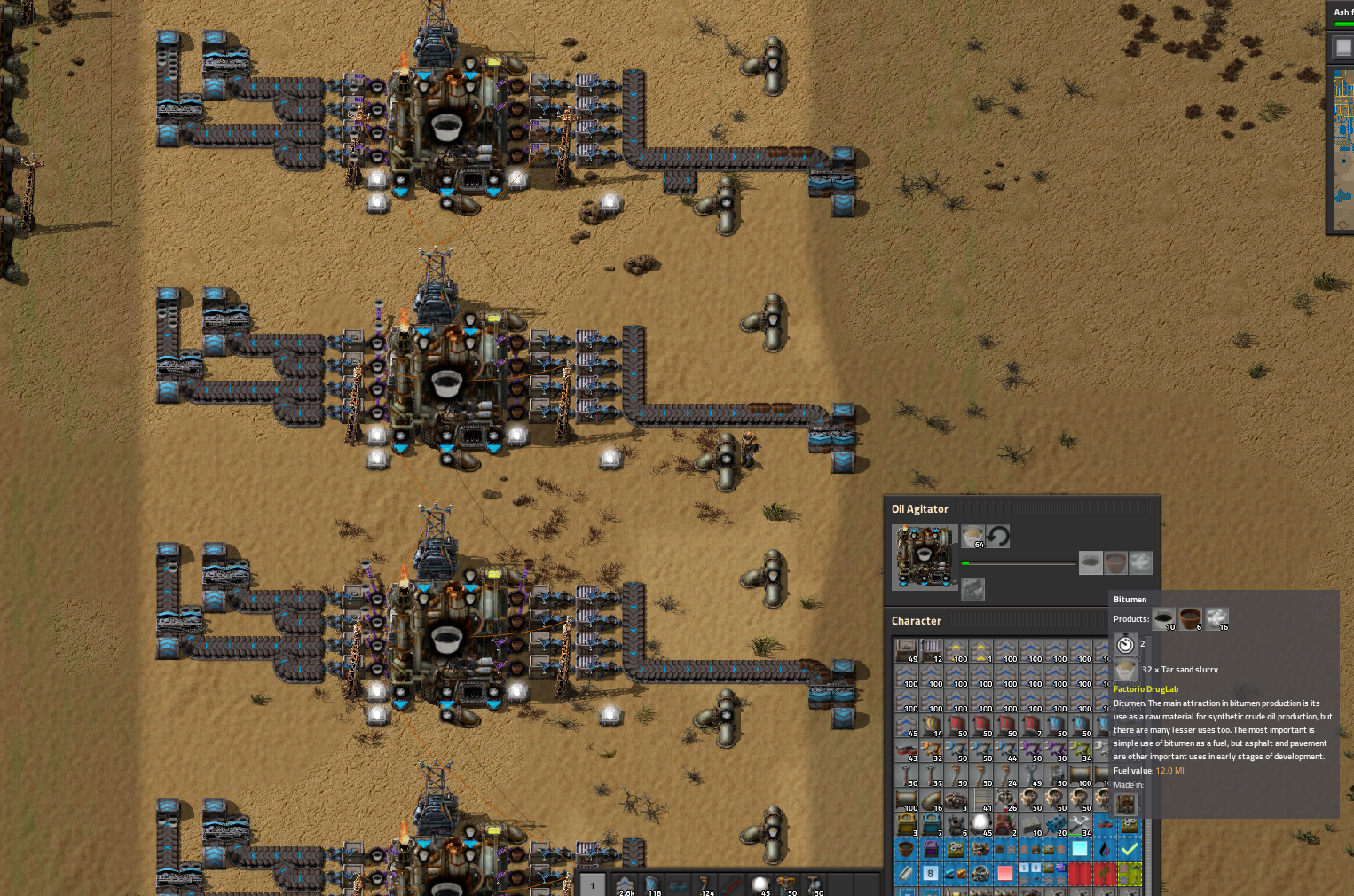

Basic bitumen I

Adds the basic necessary technology for mining and processing tar sands into bitumen and various late stage products. The main attraction in bitumen technology is synthetic crude oil production, but there are many lesser uses too. The most important is simple use of bitumen as a fuel, but asphalt and pavement are other important uses in early stages of development.

Water purification

Different ways and methods for dealing with both natural sourced water and wastewater-product from a variety of production lines. Charcoal and activated charcoal forms the basis for these technologies.

Basic bitumen II

You probably mostly know about bitumen from its use in pavement. You always kinda knew that tar and asphalt had something to do with oil. Or more vaguely with carbohydrates from the underground.

Such resources are best understood and sorted out based on their density, viscocity or their "thickness". From the most dense and viscuous bitumen to gases like methane and ethane. And off course all the better known liquid varieties in between. Like diesel, fuel oil, petroleum, gasoline. Perhaps lesser known is kerosine that is used as fuel in jet engines.

In essence bitumen is a segment of these carbohydrates in the lower, denser and more viscous part of the spectrum.

In nature you will find all of these as part of the same primordal soup that can be extracted from the underground. These carbohydrates originate from ancient organic material: Plant and animal remains exposed to high pressure and high temperatures deep in the underground beneeth us. So petrochemical materials are not a singular distinct compound like iron or gold but a mix of hundreds or thousands different compounds that gets separated out in the refining process and cleaned up according to use and need.

Limestone

Besides the use of limestone in products like asphalt, the significance of limestone is again in akaline chemistry: Limedust act as a powerful agent in disolving organic matter and purifying chemical agents.

Pneumatics

Basic technology for air compression is the basis for nitrogen extraction.

Solid fuel

One of the benefits of bitumen technology is the option to make petrochemical products in a solid form. The longchain carbohydrates makes it possible to blend a product with the desired viscoucity be it fluid, semi fluid or solid. Solid fuel have application in high density storage, in the production of high energy fuels and as a precursor in production of plastic materials.

Chemistry I & II

These technologies gives you access to advanced chemical processing. By separating nitrogen from compressed air, a range of fertilizer products are made possible. This also has obvious implications for the production of gunpowder and explosives. The main use is however in supercharging plant production with fertilizing agents like ammonium-nitrate and ammonium-sulfate.

Petrochem synthetics

The pertrochem module builds on early experience with bitument processing: Using a blend of bitumen and light oil, artificial crude oil is produced. This will supplement your needs for oil based products like plastic, solid fuel and napalm.

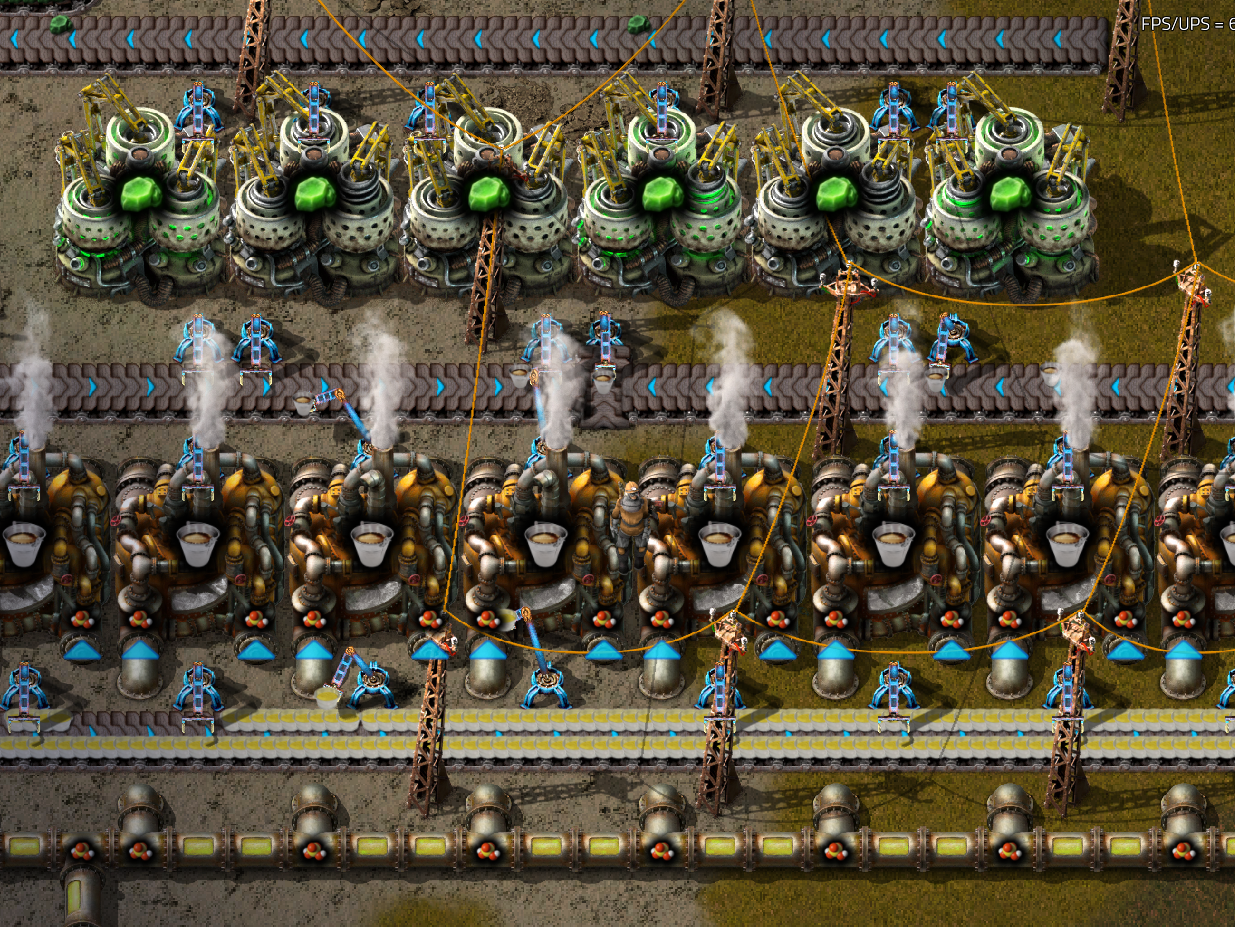

Steam cracking

Key to the use of tar sand and bitumen products is the use of high temperature steam cracking and thus transforming long chain carbohydrates into a variety of shorter/lighter fractions. Steam cracking lets refine any mixed weight oil product into various fractions. This allows the production of kerosine (essential for drug production) as well as other petrochem products.

Yellowcake processing

In production of nuclear fuels, higher yields can be obtained by use of the yellowcake prosessing of uranium. Yellowcake (also called urania) is a type of uranium concentrate powder [sic] obtained from leach solutions, in an intermediate step in the processing of uranium ores. It is a step in the processing of uranium after it has been mined but before fuel fabrication or uranium enrichment. Yellowcake concentrates are prepared by various extraction and refining methods, depending on the types of ores. Typically, yellowcakes are obtained through the milling and chemical processing of uranium ore, forming a coarse powder that has a pungent odor, is insoluble in water, and contains about 80% uranium oxide, which melts at approximately 2880 °C. (HGG)

Napalm production

One of the benefits of securing a stable high yield energy production is the variety of synthetic materials and products that petrochemical processing can provide. One prime example is the gel like substance known as napalm. This is based on a mixture of naphthenic acid and palmitic acid that can both be derived from different oil fractions.

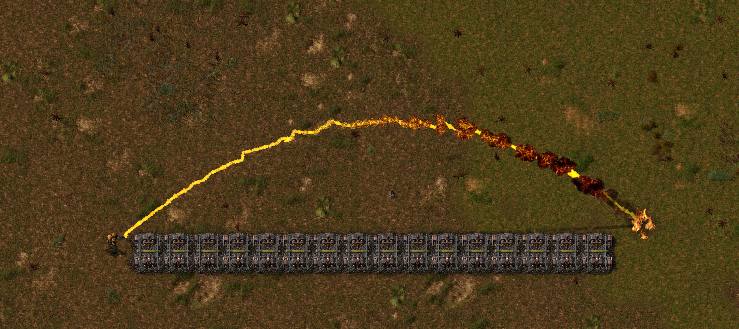

Napalm Fire Warfare

While the locals can be a bit of a nuisance, nothing calms them down like a generous dose of burning napalm. The napalm flamethrower is a specialized weapon that takes advantage of the unique benefits of napalm. This is a vast improvement over the standard issued flamethrower using light oil as best available fuel: Longer range, longer lasting fire and more damage. Avoid carelessly wandering into the inferno that you have created as the burning napalm has a long lasting and very damaging effect on organic tissue.

The module also makes the improved napalm fire turret available for those who need automated scorching of trespassers.

Fracking techologies

Hydraulic fracturing, also called fracking, fracing, hydrofracking, fraccing, frac'ing, and hydrofracturing, is a well stimulation technique involving the fracturing of bedrock formations by a pressurized liquid. The process involves the high-pressure injection of 'fracking fluid' (primarily water, containing sand or other proppants suspended with the aid of thickening agents) into a wellbore to create cracks in the deep-rock formations through which natural gas, petroleum, and brine will flow more freely. When the hydraulic pressure is removed from the well, small grains of hydraulic fracturing proppants (either sand or aluminium oxide) hold the fractures open. (HHGG, 2234)

Fracking has a huge potential in energy production but is quite demanding not only in terms of the sheer amount of hardware needed for the necessary processing, necessary research, chemistry know-how and necessary tech-skills, but also because of the need for production of injection fluid (fracking fluid). This is doubly true if you opt for a fracking based polymer production. This is an advanced technology for the mature and higly organised colony - not for your average "space-bum" camp.

Polymer production with catalysts

Polyethylene has become the most important polyolefin plastic with excellent mechanical properties, processing properties and chemical stability. High volume polyethylene placstic production is made posible with the use of nickel based catalysts.

Incompatible with RSO-mod

The way that resources are generated in Factori Bitumen is not compatible with the otherwise excellent RSO-mod. Combining the two mods results in errors and malfunction.